GHL KHD & GHL Doser 2.1 Slave Set, black, AUS (PL-1540) (REC RETAIL $1791.12)

For Wholesale pricing please click on loginThis product is unavailable

The upkeep of Alkalinity is the most important aspect of reef keeping, stability is key. If you’re looking to achieve exceptional coral growing conditions, Alkalinity testing is a must!

Keep it steady with the new KH Director. Monitor, maintain and control Alkalinity with ease.

Available in two housing color options: Black or White

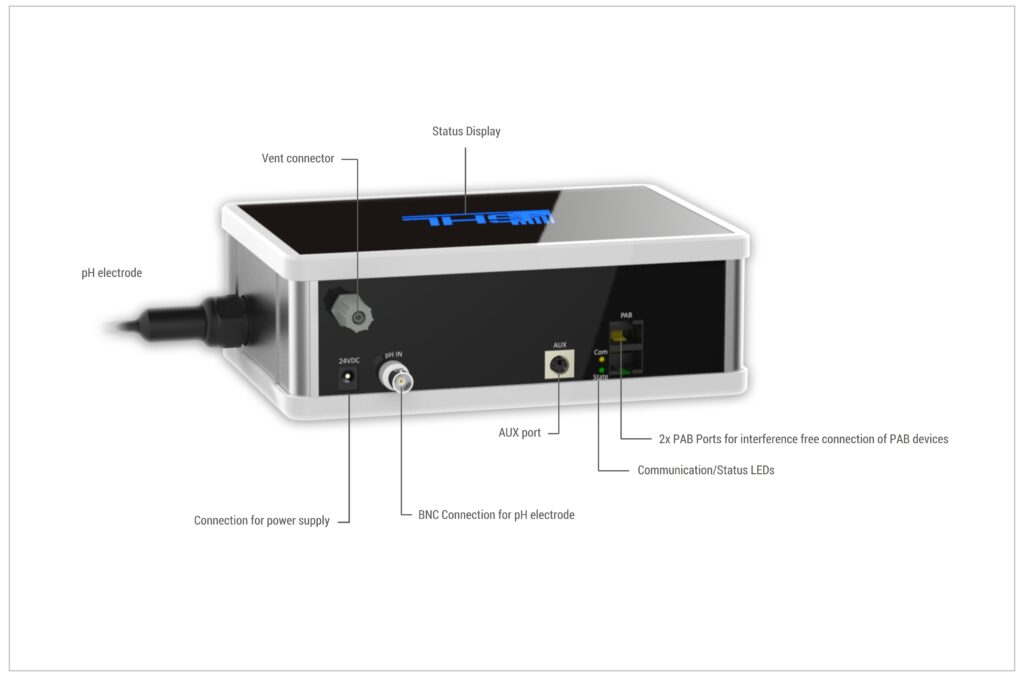

KH Director® – Features

Measure your Alkalinity with lab-grade accuracy. With only a 100 ml water sample, KH Director® can provide measurement values with 0.1° dKH accuracy.

Achieve lush corals and healthy growth.

Sit back and enjoy your passion even more with the new KH Director®.

How does the KH Director® work?

The KH Director® is designed to work in conjunction with a GHL Doser 2 (2.1) Standalone or a ProfiLux® Aquarium Controller 3 or 4 with a Doser 2 (2.1) Slave for operation.

The 2 inlets and 1 outlet of the KH Director connect to 3 dosing pumps on the Doser 2 (2.1). These 3 pumps are then responsible for accurately transferring fluid to and from the KH Director.

A sample of the aquarium water is first sent to the KH Director®. Subsequently, the KH value is determined precisely with slow addition of a further liquid (reagent) and measurement of the pH value.

The sample water is then pumped out again and collected in a separate container for later disposal.

What are the costs for reagent and pH electrode?

Here at GHL we understand the importance of on-going costs involved with automated KH monitoring and control. For the KH Director it was especially important to consider these costs and develop a highly-efficient, cost-effective product. A single 1000ml bottle of reagent can last for up to 3 months when testing is performed 4x per day at a KH value of 8. The pH electrode used by the KH Director was specially designed for KH measurement and has an average lifespan of 1 – 2 years.

Controlling the KH value

KH Director® offers the most comprehensive methods and most adjustment options for the control of the KH value, and is thus suitable for different systems, eg. Balling® (Light), Triton® or kalkwasser reactor.

Depending on the difference between the target value and the current value of KH (= control difference), appropriate activities for increasing the KH value are started.

Choose the optimal mode for your aquarium and customize it individually.

The following modes are offered:

Add-on control mode

Use between 1 and 5 dosing pumps to add liquids to the aquarium depending on the control difference, KHD automatically calculates the appropriate quantities. The dosages can be time-delayed if the liquids are not to be dosed at the same time and divided into several sub-quantities per day. It is also possible that the dosing pumps used follow a dosing schedule, the quantities calculated by the KHD are then added to this dosing schedule.

Adaptive control mode

In this mode, 1 to 5 dosing pumps can also be used to add liquids to the aquarium depending on the control difference. In this mode, you set a dosing schedule for the dosing pumps involved, and the quantities of the dosing plan are varied by the KHD. If the KH value is correct, the dosing schedule remains unchanged, if the KH value is too low, all quantities of the dosing plan are increased as a percentage. If the KH value is too high, the quantities are reduced. The quantity change is dependent on the control difference and is calculated automatically.

Calcium reactor control mode

In this mode, a calcium reactor can be down-regulated depending on the KH value.

A calcium reactor is usually operated by CO2 addition and control of the pH value; the actual pH value in the calcium reactor is measured by a pH electrode. If you select this pH electrode in the KH Director Options, the KHD can switch off CO2 if necessary (KH target value reached), otherwise the normal CO2 control is activated. This mode is only possible with a ProfiLux aquarium computer.

Configuration options

The KH Director® can be operated in two ways:

1.

The KH Director® is connected to the GHL Doser 2 (2.1) Standalone via the ProfiLux Aquatic Bus (PAB).

With this option, the GHL Doser has full control over the measurement process and behavior of the KH Director. The GHL Doser will control both its dosing pumps and the valves in the KH Director. This will allow the doser to evaluate the measurement results and calculate the KH value.

2.

The KH Director® is connected to the ProfiLux 3 (3.1, 4) and a GHL Doser 2 (2.1) Slave via the ProfiLux Aquatic Bus (PAB).

With this option, the ProfiLux has full control over the measuring process and behavior of both the GHL Doser and KH Director. The ProfiLux will control the dosing pumps in the doser and the valves in the KH Director. This will allow the controller to evaluate the measurement results and calculate the KH value.

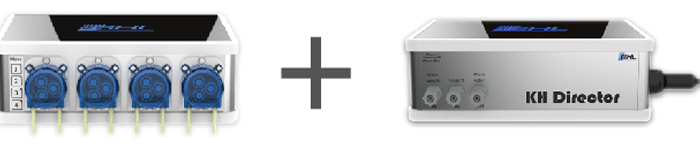

Choose the combination that suits your needs best

Whether you prefer the GHL Doser 2.1 or the ProfiLux-Slave Doser combination: thanks to the ingenious design, all devices will fit perfectly with each other no matter if stacked or positioned side-by-side.

We also offer attractive sets for the KHD and GHL Doser combinations.

Please note that only one KHD can be controlled by one master device (ProfiLux or GHL Doser Standalone), each KHD requires one dedicated controlling device. In one system (consting of one master device and slave devices) can only one KHD be present.

KH Director Sets

Operation of the KH Director requires always a GHL Doser with at least 3 pumps, depending on the configuration either as Slave or as Standalone version.

GHL offers these sets:

- KH Director + GHL Doser 2.1 Standalone 4-way

- KH Director + GHL Doser 2.1 Slave 4-way

Both sets have a significant price advantage compared to buying separately, they are offered in white and black and in these country versions: Schuko, UK, CH, USA/CND, AUS.

The sets include a PAB cable (50 cm / 19.6″).